UNITY knows the challenges of the industry - and the success factors in the areas of production, engineering and IT transformation.

We support companies in the introduction of development methods and the supporting IT, as well as the scaling and modernization of production in order to meet the new market situation due to the global/geopolitical turnaround.

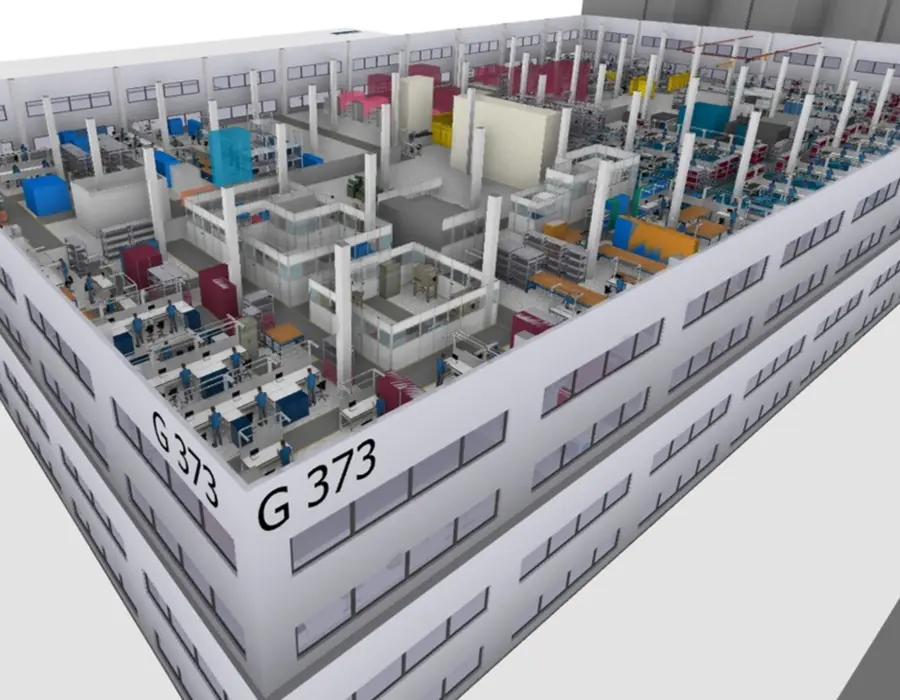

We support your team on site from the factory start-up to the achievement of performance and cost targets and optimize all levers in the entire production network, including the production IT architecture.

We enable you to react quickly to requirements and facilitate agile and virtualization-oriented development in order to bring products to market faster.

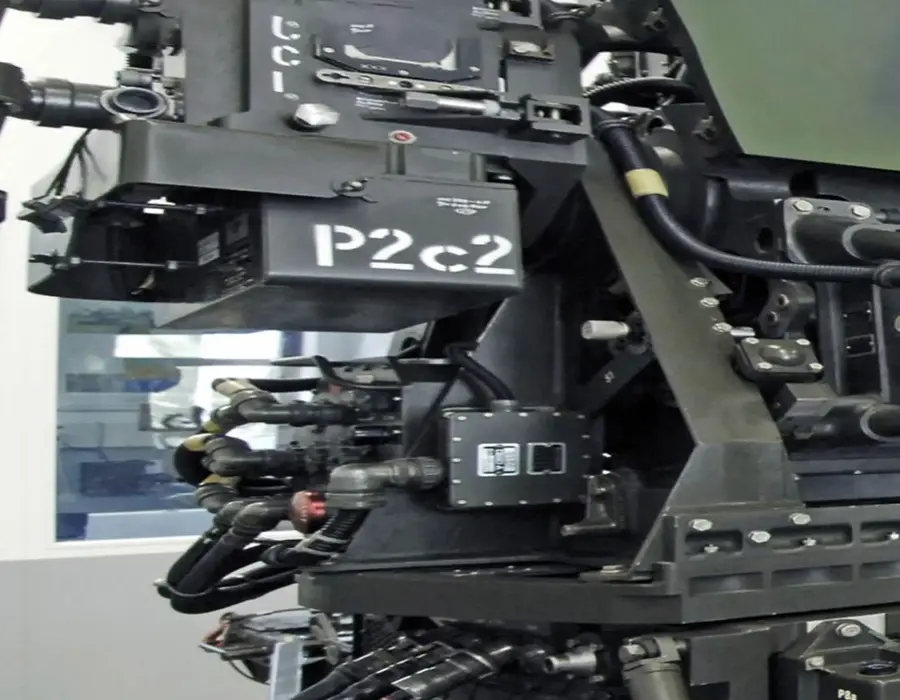

We enable the integration of networked systems and seamless interoperability for maximum performance of your products.

We examine your supply chain for its performance with regard to the planned volume growth and address risks in your supplier landscape in order to secure the necessary procurement volumes in the long term.

We develop a customized plan for the digitalization of the product life cycle and support the design, selection and introduction of PLM systems.

We empower your ongoing projects and support your employees in taking responsibility for the targeted development of products using COTS.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/5/csm_WAGO-1172772708_2cbe665207.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/a/csm_GettyImages-2158117456_eea9455ab3.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/d/csm_Header_OPP_Code_the_Product_e77248e21a.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Product-Lifecycle-Management-Beratung-1150197773_5a1e8e39cd.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/4/csm_DSC05185_bf906c444a.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/5/csm_Titelbild-LHT_wheels-and-brakes_2a7d0356a8.webp)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/d/csm_Mettler-Toledo-Header_b9642e92b6.webp)